- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

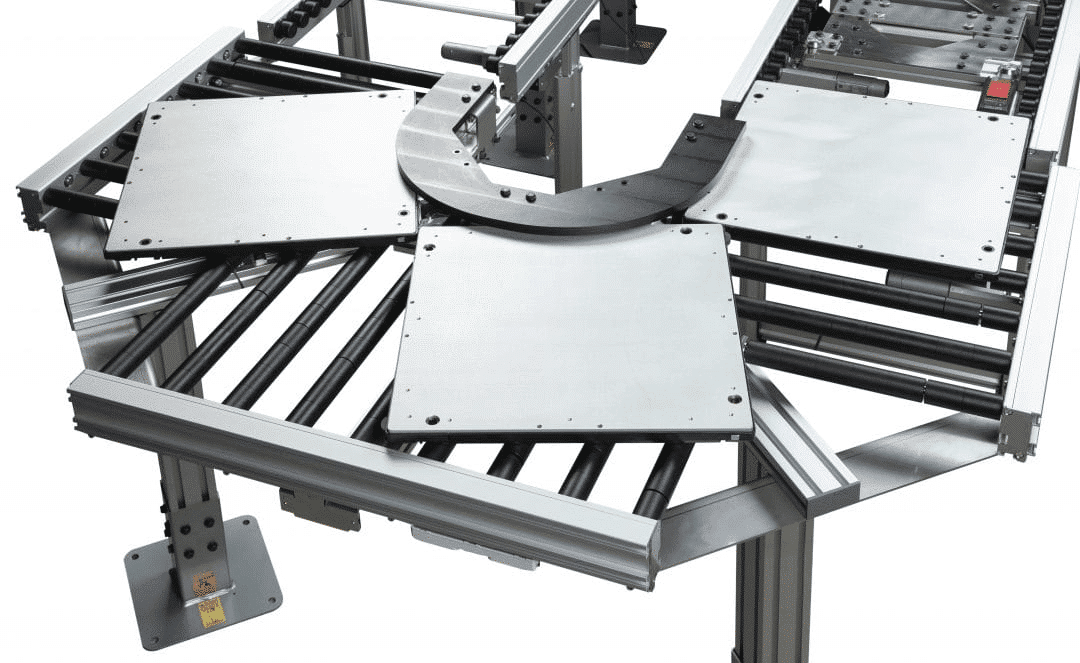

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Precision Conveyor Systems for Automation Integrators

System integrators face the challenge of creating efficient, flexible, and seamless automated production lines. At Dorner, we understand these complexities. That’s why we’ve positioned ourselves as a leading provider of advanced conveyor solutions specifically designed to meet the unique needs of system integrators.

Ready to elevate your integration capabilities? Contact our team of experts today to discuss how Dorner’s precision conveyor systems can seamlessly fit into your next automation project.

Industrial Conveyors | Sanitary Stainless Steel Conveyors | Flexible Chain Conveyors | Pallet Systems

Benefits of Dorner's Integration Conveyors

✓ Precision Indexing for Accurate Product Positioning

- Achieve positioning accuracy within .02 inches (approx. .5mm) for critical applications

- Repeatable performance at speeds up to 370 feet per minute

- Servo-driven options for ultimate precision and control

- Ideal for robotic pick-and-place, vision system inspections, and high-precision assembly

✓ Solutions for Reliable Performance

- Over 50 years of experience in conveyor design and manufacturing

- Rigorous quality control processes ensure consistent, dependable operation

- Mean Time Between Failure (MTBF) rates exceeding industry standards

- Reduced downtime and maintenance requirements for improved overall equipment effectiveness (OEE)

✓ Space-Saving Designs

- Low-profile frames as slim as 0.75 inches for tight spaces

- Flexible configurations including curved and spiral layouts

- Vertical solutions to maximize use of overhead space

- Modular designs for easy reconfiguration as needs change

✓ Industry-Best Transfers for Smooth Product Flow

- Knife-edge transfers as small as 0.25 inches for gap-free product movement

- Powered transfer options for positive control of small or unstable items

- Engineered solutions for challenging products and high-speed applications

- Minimize product damage and maintain consistent throughput

✓ Low-Profile Conveyors for Seamless Integration

- Easily integrate with robots, vision systems, and other equipment

- Improve operator access and sightlines in complex automation cells

- Facilitate easy cleaning and maintenance in sanitary environments

- Accommodate overhead obstacles and space constraints

Key Applications for System Integrators

Precision Product Positioning and Alignment

Material Handling for Lightweight Plastics and Delicate Products

Elevation Changes for Product Delivery

Robotic Interfaces for Automated Product Unloading and Positioning

Compliance with Industry Standards

- 3-A sanitary standards for food and beverage applications

- FDA-approved materials for pharmaceutical and medical device manufacturing

- Cleanroom class 4 verified for sensitive production environments

Dorner's Integration Conveyor Solutions

Industrial Conveyors

- Versatile designs suitable for a wide array of applications

- Precision engineering for accurate product positioning and movement

- Durable construction for long-term reliability

- Available in various sizes and configurations to suit different integration needs

Sanitary Stainless Steel Conveyors

- Compliance with food safety and pharmaceutical industry regulations

- Easy-to-clean designs for minimal downtime during sanitation processes

- Corrosion-resistant materials for use in wash-down environments

- Options for meeting 3-A sanitary standards and FDA requirements

Flexible Chain Conveyors

- Ability to navigate tight turns and elevation changes

- Modular design for easy reconfiguration and expansion

- Suitable for transporting a wide range of product sizes and shapes

- Ideal for creating buffer systems or managing product accumulation

Pallet Systems

- Accurate indexing for robotic pick-and-place operations

- Configurable for various pallet sizes and product types

- Options for RFID tracking and data management

- Seamless integration with workstations and other automated equipment

Seamless Automotion for Your Industry

Food and Beverage

Pharmaceutical and Medical Device Manufacturing

Electronics and High-Tech Manufacturing

Automotive Industry

Packaging Industry

General Manufacturing and Assembly

Cleanroom Environments

Large Appliance Manufacturing

Seamless Integration with Automation Systems

Integrating with Various Automation Systems

- Programmable Logic Controllers (PLCs)

- Robotic systems

- Vision inspection systems

- Sensor arrays

- HMI interfaces

Smooth Data Communication and Control Integration

- Industry-standard communication protocols for easy connectivity

- Real-time data sharing capabilities for precise control and monitoring

- Flexible I/O options to suit various control architectures

Successful Integrations with Popular Automation Platforms

- Precise motion control

- Easy programming and setup

- Flexible configuration options

- Enhanced overall system performance

Meeting Unique Integration Challenges

Customized Conveyor Solutions

- We work closely with integrators to understand the unique requirements of each project

- Our engineering team can modify existing designs or create entirely new solutions to meet specific needs

- Custom features can be incorporated to address particular product handling, spacing, or orientation requirements

- We offer specialized materials and finishes to suit various environmental conditions or industry standards

Modular Conveyor Designs

- Easy reconfiguration allows for quick adaptation to changing production needs

- Modular components facilitate simple expansion or modification of existing systems

- Standardized modules ensure compatibility and streamline future upgrades

- Reduced downtime during system changes or maintenance

Wide Range of Accessories

- Guide rails for precise product control

- Transfer plates for smooth product transitions

- Sensors and controls for automated operation

- Custom attachments for specific product handling needs

Dorner's Engineering and Support Services

Experienced Engineering Team for Custom Conveyor Design and Modification

- Our skilled engineers work closely with integrators to understand project requirements

- We offer custom design services to create unique solutions for complex applications

- Existing conveyor designs can be modified to meet specific integration needs

- Our team provides expert guidance on optimal conveyor selection and configuration

Comprehensive Installation and Commissioning Support

- Professional installation services ensure your conveyor systems are set up correctly

- We provide thorough commissioning support to verify system performance

- Our team assists with integration testing to ensure seamless operation with other automation components

- We offer guidance on optimizing conveyor settings for maximum efficiency

Training Programs for Integrators and End-Users

- Comprehensive training sessions on conveyor operation and maintenance

- Customized programs to address specific integration challenges

- Hands-on workshops for practical experience with Dorner systems

- Online resources and documentation for ongoing reference and support

Responsive Technical Support and Aftermarket Services

- Dedicated technical support team available to assist with troubleshooting

- Rapid response times to minimize downtime and resolve issues quickly

- Preventive maintenance programs to ensure long-term system reliability

- Spare parts inventory and quick shipping to support urgent maintenance needs

Dorner Tools and Delivery

DTools Online CAD Design Software

- Easy conveyor configuration and customization

- Instant pricing for faster quoting and decision-making

- Automatic generation of 2D and 3D CAD models

- Ability to save and modify designs for future projects

3D Rendering Capabilities

- We provide detailed 3D renderings of our conveyor systems

- CAD models can be easily incorporated into your overall system layouts

- Visualize how Dorner conveyors fit within your automation cells

- Identify potential challenges early in the design process

Customization Options through Dorner's Engineering Teams

- Our engineering teams can provide advanced customization services

- We offer modifications to standard designs or fully custom conveyor development

- Collaborative approach to ensure the final product meets your exact specifications

- Expert guidance on material selection and special features

Fast Lead Times for Quick Delivery

We understand the importance of timely delivery in meeting project deadlines:

- Streamlined manufacturing processes for efficient production

- Large inventory of standard components for quick assembly

- Expedited shipping options available for urgent needs

- Clear communication of expected delivery dates

Partnering with Dorner for Integration Success

Dorner's Expertise and Experience in Integration Projects

- Over 50 years of experience in conveyor design and manufacturing

- Deep understanding of diverse industry needs and automation challenges

- Continuous innovation to stay ahead of emerging trends in integration

- Proven track record of successful projects across various sectors

Collaborative Approach to Understanding Unique Requirements and Challenges

- We listen closely to your specific needs and project goals

- Our team works alongside yours to develop tailored solutions

- We offer insights and recommendations based on our extensive experience

- Flexible approach to accommodate changing project requirements

Commitment to Delivering High-Quality, Reliable Conveyor Solutions

- Rigorous quality control processes ensure consistent performance

- Use of premium materials and components for long-term reliability

- Continuous improvement of our designs based on customer feedback

- Comprehensive warranty and support to protect your investment

Focus on Building Long-Term Partnerships with System Integrators

- Dedicated account management for ongoing support

- Regular communication to stay aligned with your evolving needs

- Proactive approach to addressing potential challenges

- Commitment to your success beyond individual projects

Get Started with Dorner Today

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy